Running a successful beverage program means staying nimble with how you manage product flow, cooler space, and customer demand. Whether you’re running a high-traffic taproom, a neighborhood bar, or a restaurant with a rotating draft list, choosing the right keg sizes can have a major impact on efficiency, safety, and profitability.

If you're placing keg orders or evaluating your draft setup, here's how to determine what keg sizes best suit your operation.

ALL ABOUT KEG SIZES

In the United States, a standard keg holds roughly 15.5 U.S. gallons. Keeping up with the surplus of names and sizes (and who calls each size what) can be challenging. Every type of keg has a multitude of nicknames, making it extremely difficult to figure out how to properly size and order the kegs you need without overbuying or leaving yourself with little to no room in your beer cooler. Fortunately, with beer math, you can reduce your walk-in cooler footprint by up to 40%. This saves you money, labor, and time, and ensures staff can grab a keg safely.

When sizing kegs, the amount of beer they hold isn't the only thing you must consider. You also need to keep up with diameter, height, and direct draw for equipment. Luckily, beer math provides an all-in-one solution.

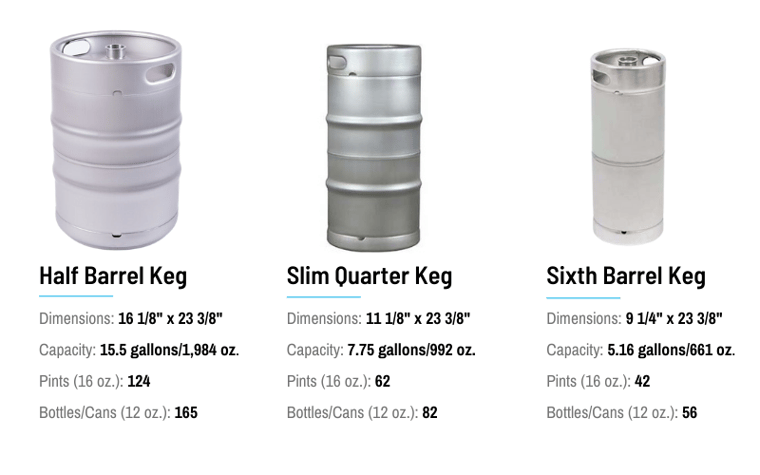

For example, let's look at a few sizes of kegs you can use for your beer cooler.

By analyzing the above data using beer math, you can take the number of products on tap and generally multiply them by three. This allows you to determine the size you need for a walk-in beer cooler while considering the diameter of each keg, how popular each product is, and how often you'll need to move an empty keg to the floor.

HOW BEER MATH HELPS

Defining your operation's precise keg needs may seem easy, but it ultimately boils down to something we like to call beer math. By gathering data that shows how many ounces you pour in one week and THEN reviewing other specific operational needs, we can create a Draft Beer Analysis (DBA) formula to design a custom beer cooler shelving solution.

Through consistent monitoring over the years, we've determined that no matter how many taps you have in your beer cooler, 1/3 of those taps will move faster than other products. For more popular products, you'll want easy shelving access so that taps are interchangeable and require little to no time consumption. Additionally, with beer math, we can decipher which products are cost-efficient and which are going to waste, allowing you to put money back into your budget and focus on other tasks.

NEED HELP?

If you're still uncertain of how beer math can help you size kegs to meet product demand while improving the safety and workflow of your walk-in beer cooler, contact us today so we can sit down and do the math with you. Our turn-key formula is the solution you need when getting back into the swing of things. As we all adjust to the new day trends, wasting beer and losing money isn't part of our game plan.

We look forward to helping you understand how beer math can cut back on waste and improve the overall service spectrum when customers order a drink.

How many kegs do you need?

We've put together a handy calculator that will help you find out. Check it out👇